Boiler Cleaning Chemical

Boiler Cleaning Chemical Price And Quantity

- 20 kg Liter

- 100.00 - 300.00 INR

Boiler Cleaning Chemical Trade Information

- 1 Liter Per Week

- 1 Week

Product Description

Purpose of Boiler Cleaning Chemical :

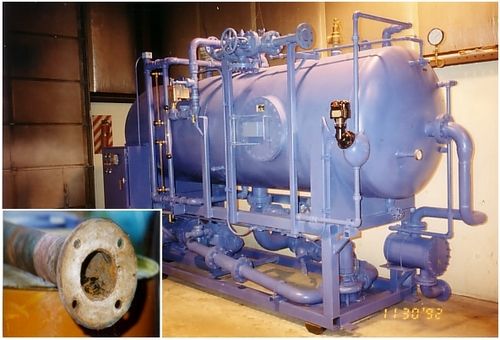

Chemical cleaning of boilers/ heat exchangers is done to avert tube failures & improve unit accessibility. Tube failures in low pressure boilers are usually the effects of creep, which occurs when interiors make immoderate metal temperature. Another causes behind the tube failures are: small amount of deposit, temperatures below the creep limit, caustic corrosion and hydrogen harm, which happen only in the existence of deposits. Deposits developing both from fabrication & procedure should be considered as potential troubles.

Each pressure part of steam generator may be dependent to heat treatment, during the hours of :

- Fabrication

- Erection

- Forming operations

- Stress alleviation

- Bending

- Welding

An oxide named as "mill scale" is produced, when carbon low alloy steels are opened to high temperatures. Mill scale on boiler/ heat exchanger tubing is usually very thin except the areas near welds & bends. Despite the initial uniformity, the crispness of its cooling produces flaking. The non-uniform surface it makes can result in corrosion. Mill scale is quickly eroded from the steam yielding opencast & may be redeposited in faultfinding areas. Acid cleaning prior to operation takes out mill scale and atmospheric rust, which necessarily compiles to some level during erection.

When a boiler set into service, solid components may enter the units through feed water. Some part of the insoluble can be foreseen to deposit on surfaces. If not separated the deposits after being collected can lessen the amount of these materials. Complete exemption from deposition is not possible in high pressure. The chemical cleaning during the service life of the equipment is mandatory and should be accepted as a regular upkeep practice. The service cleaning in every 3 to 4 months is essential and should be increased if the operating history of unit is extended.

OFF LINE BOILER CHEMICAL

CLEANING CHEMICAL is planned to remove the scaling & corrosion products from boiler, heat changers, cooling water circuits etc. It is a liquid preparation that removes hardness & low amassed silica scales that can be abstracted offline by circulating its diluted chemical solution. It is a harmonious formulation of corrosion inhibitors, dispersant wetting causes and hydrochloric acid.

BENEFITS

POWERFUL DESCALENT.

BOILER CHEMICAL is harmless & non-caustic for descaling as it dissolves hardness scales rapidly & completely.

SAFE FOR METALS

BOILER CLEANING CHEMICAL comprises a synthetic polymeric corrosion substance, which makes preserving film on the parent metal opencast and prevent acid attack.

DETERGENT ACTION:

BOILER CHEMICAL has a wetting agent, which changes the active oil grease of deposits. The detergent act of Aquablend-DS during the water flushing, loosens algae, dirt, silt etc.

APPLICATION:

CLEANING CHEMICAL should be treated in 5-10 % solution in water and warm water should be used for faster action. Usually the amount of scale needed reckons upon the operational premise quantity of scales. We will give technical help for optimal dosage in accordance with conditions and instrumentation.

STORAGE & HANDLING:

BOILER CLEANING CHEMICAL should be stocked in an air tight container. It should be stores at a cool & dry place, away from the sunlight. Should be washed in the case of direct contact.

BOILER CLEANING CHEMICAL is available in 20 Kg & 35 Kg packed in HDPE CARBOY.

AQUABLEND - XL

Online Boiler Cleaning Chemical

BOILER CLEANING CHEMICAL is planned to withdraw the scales from boiler online. It is a liquid preparation that slowly removes calcium, iron and magnesium scales at the time of operation.

BENEFITS

NO SHUT- DOWN

BOILER CLEANING CHEMICAL incorporates powerful sequester-ants and dispersing agents, which take away assembled sludge from an operating boiler. It obviates the shut down that is required for removal of pipe lines & equipments.

NON-CORROSIVE

BOILER CLEANING CHEMICAL is innocuous & non-corrosive for online descaling of boiler and protect the metal surface from corrosion.

EASY TO USE

CLEANING CHEMICAL can be used with boiler water treatment chemicals and doesnt require any particular dosing-arrangement.

COST EFFECTIVE

BOILER CHEMICAL should be used when boiler is due for descaling or you suspect a forming scale inside the boiler.

APPLICATION

BOILER CHEMICAL should be treated at 10-20 ppm. Dose the mixture in boiler feed water line until scale is separated from the boiler. We will provide technical help for balanced dosages in compliance with operating conditions and dosing system.

STORAGE & HANDLING

BOILER CHEMICAL should be stocked in an air tight container, at a cool & dry place. Wash completely with water in case of interaction. Strictly suggested not to swallow.

CLEANING CHEMICAL is accessible in 20 Kg compact in carboys.