Thermal Fluid Systems

Thermal Fluid Systems Price And Quantity

- 2000.00 - 6000.00 INR

- 20 Kilograms

Thermal Fluid Systems Trade Information

- 1 Kilograms Per Week

- 1 Week

Product Description

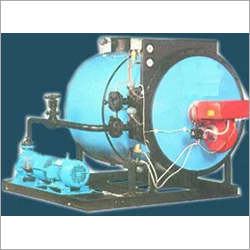

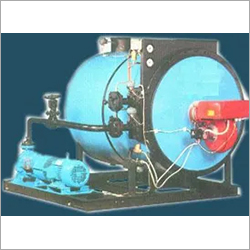

Thermal Fluid Systems

We export and supply Fluid Systems which is the heating media which transfer the heat in close loop cycle.

It is available in two forms

- Mineral heat transfer oil.

- Synthetic heat transfer oil.

Mineral oil can withstand maximum temperature up to 280C. Synthetic oil can withstand maximum temperature up to 310C.

Continuous use of Thermal Systems results in to deteriorating of Thermic fluid.

The main causes for deterioration are oxidation & cracking.

- Oxidation: Oxidation at higher temperatures causes formation of sticky carbon. This causes choking of the system & reduced heat transfer efficiency & also produces acidic products. These add to viscosity of the oil along with increase in corrosion rate at internal parts of thermic fluid heating system.

- Cracking: Overheating of the thermic fluid caused by insufficient circulation. This results in to de-polymerization of long chain compound. This localized heating above cracking temperature of oil. Cracking results in to release higher hydrocarbons which increases viscosity & reduces flash point of thermic fluid. Polymerization cause by these hydrocarbons form deposits reducing flow rate & heat transfer efficiency.

- Parameter Of Fluid Systems To Be Checked:

- Appearance

- Moisture content

- Flash Point

- Fire Point

- Auto ignition temperature

- Kinematics Velocity

- Density

- Specific Gravity

- Coefficient of Thermal Expansion

- Average molecular weight

- Pour point

- DETERATION OF THERMIC FLUID:

- PARAMETERS:

- Reduction in flash point.

- Increase in Viscosity.

- Co lour changes to darker shade.

- Increase in acid no.

- Lowering of boiling point.

- EFFECTS:

- Reduction in pump circulation in pump circulation rate.

- Reduction in heat transfer efficiency.

- Higher fuel consumption.

- Less Productivity

- Reduction in life.

- Safety hazards.

CHEMICALS USE FOR THERMIC FLUID DE CARBONIZING ARE:

- Thermin- DC

- Fueline-R

COMPARSION BETWEEN

FUELINE R (OFFLINE PRODUCT)

AND

THERMIN-DC (ONLINE PRODUCT)

Sr. | Parameter | Fueline-R | Thermin-DC | |

| ||||

Base | Synthetic Lude Oil | Synthetic Thermic Fluid | ||

Strong carbon dispersant. | Organic oil based | Organic oil based | ||

Viscosity reducer. | Higher mol. Wt. | Higher mol. Wt. | ||

Penitratant | Synthetic | Synthetic | ||

Ionic emulsifier | Organic 10m | Organic 10m | ||

Corr.inhibitor | Built in base | Built in base | ||

PROCESS BLENDING | COLD | CLOD | ||

| ||||

PHYSICAL & CHEMICAL PROPERTIES. | ||||

| ||||

pH | Acidic | Acidic | ||

Specific Gravity | 0.75 0.85 | 0.75 0.9 | ||

Viscosity | 15-20cst | 18-30cst | ||

Flash Point open cup | 140-160C | 190-200C | ||

Working temp.-close lop | 120C | 310C | ||

| ||||

EFFECT ON THERMIC FLUID. | ||||

| ||||

Application | Offline | Online | ||

Thermic fluid after treatment | Complete drain | Reused as normal | ||

pH | Increases slightly | Increases slightly | ||

Specific Gravity | Decreases nominally | Decreases nominally | ||

Viscosity | Decreases drastically | Decreases drastically | ||

Flash Point | Remains same | Remains same | ||

Acid Valve | Decreases slightly | Decreases slightly | ||

Auto ignition Temperature | Remains same | Remains same | ||

Pour Point | Decreases | Decreases | ||

| ||||

CASES OF WORKING. | ||||

| ||||

|

| FUELINE-R | THERMIN-DC | |

| Working Conditions | Flash point below 150C | Flash point below 150C | Flash point above 150C |

| Type of action | Offline work | Online work | Online work |

| Working temperature | Less than 100C | Up to 300C | Up to 300C |

| Dose | 7-10% | 3-5% | 3-5% |

| Down time | 24-36hrs. | Nil | Nil |

| Addition when | Immediate | 4 day prior to drain | Immediate |

THERMIN DC

ONLINE THERMIC FLUID DE CARBONIZING CHEMICAL

Thermin DC is a powerful formation which is a combination of strong carbon dispersant, emulsifier & corrosion inhibitor.

This formulation is used effectively for online de Carbonization of entire thermic fluid system.

FUELINE R

PRODUCT DETAILS ADVANTAGE OF USING FUELINE

Fueline R is powerful formulation which is combination of strong carbon dispersant, emulsifier & corrosion inhibitor.

This formulation is used effectively for de carbonization & descaling of entire thermic fluid system. This is an ideal solution

to be applied before replacement of thermic fluid from any system.